If we know that teaching operators to a test or a specific machine doesn’t work that well, why hasn’t training changed in decades? One company set out to change the game with on-demand virtual reality (VR) training, which offers promise in teaching the concepts of the process resulting in more well-rounded staff that can move to other machines and facilities.

Virtuosi® is a training platform developed by Quality Executive Partners, Inc. (QxP), a management consulting firm specializing in compliance consulting for the life sciences industry. The company’s leadership has extensive backgrounds as former executives at global pharmaceutical firms.

“In the pharmaceutical industry, the way we educate people has regressed a bit since many of us started our careers, myself in the ’90s,” says Brian Duncan, Chief Operations Officer at QxP. “We saw that foundational education just wasn't being done anymore. Predominantly it's not really education as much as it is teaching people to follow a procedure, a step-by-step process.”

Train the trainer challenges

One issue is that subject matter experts (SMEs) are highly leveraged within most organizations, spending much of their time troubleshooting issues and establishing or updating standards and procedures. This leaves little time or opportunity for company experts to engage in a meaningful way with educating staff at the shop floor or benchtop level. Second, some technically skilled operators aren’t natural teachers, at times lacking the understanding of what a student needs to know or what they may find challenging.

These were both common themes the consulting company encountered among small and large organizations. Often training means sitting in a new employee orientation session with days of mind-numbing slideshows, where somebody points out what might be on a quiz.

On-the-job (OJT) training typically follows more of a see, do, teach approach. A trainer points out some critical concepts, watches the new employee try the technique, and then signs them off. “That has a lot of limitations,” Duncan says. “Looking at high-risk operations such as aseptic manufacturing, the employee may learn, ‘I don't put my hand there,’ but they should really know the principle of why you don’t put your hand there. Why do you need to sanitize surfaces and equipment? We realized that there was a need, and we wanted to find a way that we could help these companies in finding a way to scale quality, technical education.”

Why VR?

“We had tried to develop educational materials, training courses, and certification programs for individuals to leverage these SMEs from within pharma organizations, train them on the right content so that they could go out and teach others… a train the trainer concept,” explains Duncan. “We found out very quickly that has a lot of limitations. On one such project, for example, we prepared a comprehensive program of microbiological content only to eventually certify six of the initial 65 candidates resulting from limitations in SME availability, breadth of technical knowledge, or teaching capability.

The company looked at a number of digital video platforms alone, but VR piqued the company’s interest because it seemed to be the only medium that could transcend boundaries in a remote sort of way to enable both expert instruction and hands on skill building focused on the “why.”

When QxP decided to go down this road, they studied the landscape. “No one was using VR in pharmaceutical education to fully leverage these capabilities,” Duncan explains. So they asked themselves, who uses VR for education and has learned to do it successfully? “That led us to the medical surgical community,” says Duncan. They focused on lessons learned and publicly available scientific studies with control groups and real data. “Some of the data we see is that folks who are trained in VR-assisted curricula are 29% faster and six times less likely to make a mistake than when they try it for the first time on their own.”

A setup of a computer, hand devices, a headset, and a couple of sensors, can immerse trainees in an environment to practice.

A setup of a computer, hand devices, a headset, and a couple of sensors, can immerse trainees in an environment to practice.

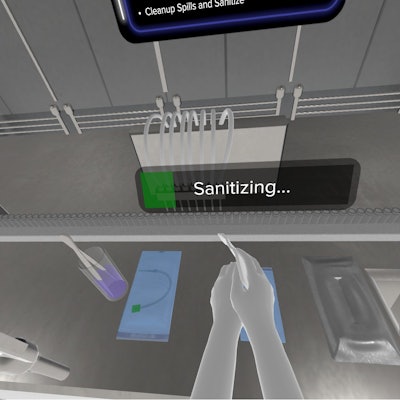

“We wanted to bring that same impact to the pharmaceutical industry and to scale learning. With VR, all you need is a setup of a computer, hand devices, a headset, and a couple of sensors, and you can actually be immersed in an environment and practice. The great thing about practicing is you can make mistakes, and when you make mistakes, depending on how you program your VR, it can coach you in real time,” says Duncan. “And unlike an OJT trainer, it knows exactly where the trainee put their hands. It's never distracted, and it's always watching exactly what you do.”

Nuts and bolts

The Virtuosi product itself is set up with episodes—technical modules—that build upon one another with the focus on educating staff in the foundational principles explaining the “why” behind the tasks performed every day. Such valuable, contextual understanding enables critical thinking and directly influences the skills and behaviors needed to perform sterile manufacturing and microbiology testing, and to do it well.

Technical experts worked to lay out a comprehensive series of topics with defined learning objectives, then leveraged VR to take the trainees’ understanding and lessons learned into the actual environment in which they would be operating. For example:

- People can enter a sterile filling line to learn about aseptic connections, seeing an exercise and then trying it on their own.

- Trainees can learn critical aspects of environmental monitoring (EM) programs. “Students can figure out what goes into designing an EM sampling plan within a manufacturing filling suite. What are my hot points and why? What kind of samples do I pull from there and why? What factors do I need to consider in developing that sampling scheme?” says Duncan.

“Our technical experts have spent entire careers building sterile facilities, building course materials, and teaching these topics. We paired deep subject matter expertise with a thoughtfully selected VR partner,” Duncan notes. “We selected a VR partner that used predominantly, classically trained engineers, who knew and appreciated the science behind what we were trying to achieve, in addition to computer programming. So when we look at things like airflow, they know the principles of fluid dynamics behind what we are creating.”

The company saw a need to move from a check-the-box, qualification-based training paradigm back toward educating on principles and providing on-demand, experiential educational opportunities.

The company saw a need to move from a check-the-box, qualification-based training paradigm back toward educating on principles and providing on-demand, experiential educational opportunities.

In total, there are 31 episodes in the first series of Virtuosi, each about 60 to 90 minutes long. Complimenting the technical lectures delivered via a cloud-based multimodal platform are 18 VR interactive experiences (approximately 30 minutes each). Depending on the number of iterations one goes through in the VR sessions, it’s approximately 80 hours of content. Within each episode are coached process checks to ensure engagement and understanding, and there is a knowledge assessment at the conclusion of each episode that must be passed in order to receive credit.

The company received support from the UK’s Medicines and Healthcare products Regulatory Agency (MHRA), which reviewed the program as a primary beta partner in the pilot program in advance of its commercial launch in Q1 of 2020. “MHRA promotes innovation across all stages of the pharmaceutical lifecycle and provides regulatory advice to stakeholders through initiatives such as its Innovation Office. The MHRA’s inspectorate welcomes the opportunity to support and adopt new technology such as innovative approaches to delivering education,” an MHRA spokesperson told Pharmacy Business.

The Power of VR

The concept of a smoke study is fairly understandable, but VR allows the student to see things and interact with the environment in a novel way, opening myriad opportunities to engage learners through experiential learning models. VR not only lets you see the movement of airflow; but it can also place you inside the filling line to interact with the airflow in the form of visible smoke.

Duncan says, “In the past, demonstrating the same principle in a video format would literally require putting a person in a room to watch 12 hours’ worth of smokes studies,” looking for events such as the background interfering with the flow, or a door where there is turbid airflow. “To show interrupted unidirectional airflow through classical methods, a company would need video that was very clear, had good contrast and backgrounds to see the smoke—and a bad study because we had to see disrupted air that you're not supposed to see. VR not only allows you to see it, but you can also interact with it and create those conditions in real time to understand first air principles and the interaction between differently shaped objects and their positions and movements on a filling line.”

Principles vs OJT training

The goal with Virtuosi is to teach principles beyond operators gaining muscle memory for grabbing forceps and the like. “It's not intended to tell you push button A, B, or C. It actually was a lot harder to make the VR environments widely applicable, as opposed to a very specific setup. VR is not a direct replacement for hands-on, on-the-job training and qualification, nor should it be,” notes Duncan.

Once an operator goes through the Virtuosi episodes, the idea is that they're going to understand the founding principles that will enrich and accelerate their progression through hands-on training certification on a specific line or setup, significantly reducing the potential for human error or potential for negative impacts to classified environments. Further, trained staff will be much more capable to move to a different area in the plant or a different job altogether—it doesn't have to be the same machinery.

A big training issue has come with the explosion of personalized medicine and gene therapies. “We talk to the big pharma companies and ask how they’re training their people for these products. They say, ‘We’re bringing in our best operators from our most advanced site to work in producing cell and gene therapies.’ But many times these employees are transitioning from working in isolators and highly automated environments,” says Duncan.

Throwing operators into a BSC (biological safety cabinet) won’t be familiar—these are open processes based on scaled-up development. “There’s a lot of physical manipulation, open containers, and transfers, so it's completely 180 degrees out of phase with how they've been trained classically.”

Learners go through the course episodes, and then when it’s time to practice what they’ve learned, the student will be prompted to go to a dedicated VR workstation, located on-premise at the facility.

Learners go through the course episodes, and then when it’s time to practice what they’ve learned, the student will be prompted to go to a dedicated VR workstation, located on-premise at the facility.

The hidden cost of limited training

Operational budgets in pharmaceuticals are pretty tightly squeezed, and some companies may be worried about adding training expenses. But it’s important to acknowledge the (often hidden) embedded costs people call "the cost of doing business.”

“Training budgets have become cut, and cut, and cut, and that's the reason why it's so focused on SOP transactional training,” Duncan says. It’s important to understand the blind spots in costs of traditional training. In addition to helping new clients put together ROIs for their investment decisions, QxP also implements careful monitoring programs to gather metrics on these hidden costs.

While plants budget for rejects and scrap, there are less-tangible costs that companies aren't often good at quantifying or capturing. Major investigations, health authority observations, additional studies, unplanned shutdowns, and repeated validation exercises take staff time and money to address. “But even if you just look at the cost of rejected materials… we're finding that most companies see an ROI of a two to three-year time frame or less due to reductions in human errors of 25% or greater.”

As a number of companies install filling lines for training elsewhere in the facility, VR may be a more cost-effective option. “Typically this goes through a capital budget, not directly through the training budget, but the expense of adding a whole training line can be orders of magnitude more than VR training,” says Duncan. “It's a matter of awareness of these costs, and how they reconcile the investment relative to the company. A filling line for training purposes and SMEs to train people incur a lot of embedded costs, and the plant footprint costs a lot.”

Not just a shiny new toy

The pharmaceutical industry as a whole has lagged behind similar manufacturing industries in adopting new technologies and innovation in manufacturing. To address this, many companies decide they want to do something innovative, and it can lead to an exercise in “doing something in VR.” Duncan says that companies have to be careful not to fall for the shiny object, instead of what they’re trying to achieve and what can VR do to help with addressing real problems.

Many times, companies partner with a VR firm—with no technical pharmaceutical experience—that can render their specific filling or packaging line in VR. They can mimic the setup or have something illuminate when a button is pressed, but typically these are still instructor-led, with somebody standing by to judge performance.

With the Virtuosi platform, the coaching is multimodal with audio, visual, textual, and graphical interfaces. Operators get to learn and make their own mistakes at their own pace in a safe and private environment—without fear of embarrassment or judgement—where everyone is being trained to the same standards because they're going through the exact same algorithms to ensure consistency.

It also may be an answer to the ever-growing issue of distraction. “The great thing about VR, too, is that you'll be getting instruction, and if you turn your head and look away from what we're trying to demonstrate, the VR simulation pauses. So you can't look at your cell phone in VR—you do have to pay attention.”