This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Dunn Industries, a Tekni-Plex business, is highlighting its acetal Catheter Core mandrel technology used to manufacture minimally invasive catheter shafts at MD&M West, February 5-7, Anaheim Convention Center, Anaheim, California, Booth 2033.

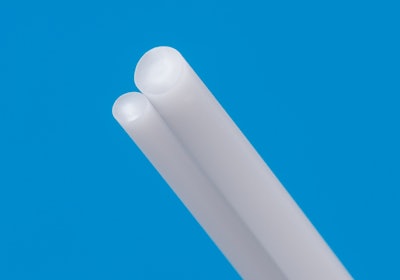

Medical catheter manufacturers throughout the world use Dunn’s Catheter Cores to retain critical lumen tolerances during extrusion, braiding, coiling and jacketing processes. Low friction material properties and ultra-smooth surfaces allow these cores to be easily removed after catheter shaft assembly. They are available in precise diameters from 0.020 to 0.250 inches with tolerances as low as +/- 0.0005 inches.

Dunn’s proprietary process is used to precision extrude a solid acetal rod, which is supplied on continuous spools for ease-of-use during catheter processing operations. The cores maintain critical inside wall dimensions during initial extrusion of the inner polymer layer, application of the reinforcing fiber layer and extrusion or ”jacketing” of the outer layer.

Reinforced tubing is frequently used for diagnostic and guide catheters, high-pressure contrast injection tubing and other minimally invasive devices. Adding reinforcement to the plastic tube wall improves torque transmission, kink and internal pressure resistance, and column strength.

Dunn also manufactures custom medical tubing for diagnostic and interventional devices from a wide range of thermoplastics. These include polyether block amides (PEBAs), thermoplastic polyurethanes (TPUs), thermoplastic elastomers (TPEs), polyamides, polyolefins and much more. Tubes are available with diameters as small as 0.008 inches (outer diameter) x 0.004-inches (inner diameter), and diameters as large as 0.480 inches. Configurations include single and multi-lumen, coextruded layers and stripes, and longitudinal wire or fiber reinforced.