Key Takeaways:

- Technological advancements in the development of the latest at-home testing kits and devices, and the rise in the prevalence of diabetes, has increased the need for rapid testing, creating an opportunity for the at-home testing market.

- The pandemic normalized at-home testing but also spurred a broader consumer interest, across a wide demographic, in using at-home testing to explore different aspects of their health.

- Manufacturers should break down the entire process – from receiving the kit to obtaining the results – and consider how packaging might be used to improve each step.

At-home medical tests, also known as home use tests, are kits available for purchase online or at local pharmacies and supermarkets. These kits enable users to test for, screen, or monitor specific diseases and conditions from the comfort of their home. According to a recent Allied Market Research report, the global at-home testing market size was valued at 16,663.94 million in 2021 and is estimated to surpass 45,582.24 million by 2031, growing at a CAGR of 10.5% from 2022 to 2031.

Common at-home tests include:

- Pregnancy tests

- Blood glucose tests for diabetes management

- Fecal occult blood tests for colon cancer screening

- Tests for infectious diseases like hepatitis, HIV, and COVID-19

- Genetic tests indicating risk for certain diseases

There are two main types of at-home tests:

- Self-tests: These involve collecting a sample (such as blood, urine, or saliva) and applying it to the test kit as directed, providing immediate results.

- Self-collection tests: These allow you to collect a sample at home and then send it to a laboratory for analysis. Results are typically provided by your healthcare provider or through an online portal.

According to the aforementioned report, technological advancements in the development of the latest at-home testing kits and devices, and the rise in the prevalence of diabetes, has increased the need for rapid testing kits, creating an opportunity for the at-home testing market.

That, coupled with the easy availability of self-testing kits at online stores and pharmacies, since a prescription is not required, is also boosting market growth. Then there was the COVID-19 pandemic, which increased awareness among people regarding the use of self-testing kits.

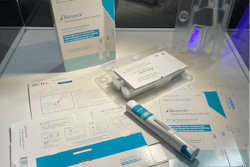

OptimallyMe offers users a science-backed, 100% personalized health dashboard to help users understand and improve their health, by using the company’s at-home blood and microbiome test kits. These kits includes instructions, a container for the sample return and a pre-paid shipping label to make at-home testing simple.

“We wanted our packaging to have an approachable, yet quality feel,” said Edward van-Harmelen, Founder, OptimallyMe. “It’s the first time our customers come into physical contact with our brand and a positive impression is vital.”

To do that, the company partnered with packaging design studio Burgopak, to create multi-component packaging that makes testing simple.

As part of a bigger story aside from OptimallyMe’s kits, I reached out to Burgopak to ask about the at-home testing market and how packaging plays a role in user experience. Alexander Parker, Head of Design, Wellness, at Burgopak, and at sister company Duallok, weighed in on this trend and the important role packaging plays.

HCP: Can we talk about the boom in at home testing? Did this originate from COVID- 19 tests?

Parker: It was a contributing factor in several ways. Health and wellness at that time was a growing market, with individuals seeking to be empowered and take control of their own health. The pandemic normalized at-home testing but also spurred a broader consumer interest, across a wide demographic, in using at-home testing to explore different aspects of their health.

The scale and ambition of the testing initiatives led many to consider what else might be possible or achievable through at-home testing—government, businesses and healthcare providers.

HCP: What kind of things are consumers testing for at home?

Parker: It’s certainly a broad spectrum. At-home test kits can be used in disease detection, for instance COVID-19, sexually transmitted infections, and cancers. As well as for insights, such as cholesterol, liver function, kidney function, and wellness issues such as vitamin deficiencies. They are also used within hormonal and reproductive health as well as general health.

Genetic testing can be used to understand if you’re at higher risk of certain diseases. They can also be used in exploring a user's ancestry.

There are many different sample types - blood, urine, stool, saliva, nasal/throat swab – and there are many different devices that are used in specimen collection. The scale is broad too – from curious individuals to national screening programs.

A kit may use devices that are self-testing, delivering the results then and there. Others are self-collection, where the devices are used to collect a specimen before returning to a lab for analysis. I think it’s important to note that the test kit itself is often just one part of a bigger system used to deliver the intended results.

HCP: What else is spurring growth in this segment?

Parker: I think this idea of quantified self, looking for data-driven insights through ever smarter wearables, apps, or devices does perhaps inspire the use of test kits to explore other aspects of health and wellbeing. There is opportunity to use test kits and the insights as a way of making personalized product recommendations.

HCP: How can product owners maximize the impact of at-home test kit packaging?

Parker: Great question. It’s important to aim higher with regards to what a test kit can do and recognize that its impact can be felt across many different stakeholders. Priorities can be very different between products, so they need to be made clear when starting the design process. Work closely with designers, engineers, and manufacturing partners to develop a kit that works beyond the immediate function.

User experience and ease of use: Consider how the packaging might be able to contribute to the correct completion of a test. Positive interactions with the packaging are going to help build trust and confidence as well as a strong brand image.

Stakeholder engagement: This includes everyone involved, from the end-user to fulfilment partners, logistics teams, and labs. It’s important to understand their needs and learn from past challenges.

Prototype, test, and refine based on learned insights. For example, you might find that reducing the kit size could bring costs down by fitting into a less expensive postal bracket; small tweaks like these can make a big difference.

Packaging as a brand asset: don’t undervalue the importance of the kit within a product offering. This might be a customer's first and only physical touch point for the brand and their experience will influence their opinion. There’s importance beyond the functional characteristics of the packaging.

Packaging as a marketing asset: again, depending on the product, the packaging can become an important visual asset used across websites and media. Customers may share unboxing videos or photos within reviews, generating exposure and supporting word-of-mouth sales. This is all return on your investment.

Print and artwork: such an important part of the execution of any packaging. Make time and allocate resources to explore artwork beyond looking at regulatory compliance and build a strong visual identity.

HCP: How can packaging improve user experience?

Parker: You need to break down the entire process – from receiving the kit to obtaining the results – and consider how packaging might be used to improve each step.

Instead of loose components and an IFU (instructions for use) rattling around inside a box, a small design intervention might be simply adding a lid inside. Now we can place the IFU on top as the first thing the user interacts with. Perhaps on that lid we can add a QR code link to a video tutorial and maybe viewing that also requires the kit registration.

A progression from there might be arranging those components in order of use – it could be as granular as step-by-step or grouped into prepare, collect sample and return. Is it accessible? A cluttered or confusing kit could cause frustration.

As well as looking for that functional benefit we’re working on trust, confidence and in some cases value. Given the diverse nature of what test kits are used for, and the spectrum of costs, it’s also important to keep in mind what the customers’ expectation might be. Poor quality materials or execution can infer an inferior product, so you need to consider the details. If something is meant to tear open, ensure that it does so cleanly, reliably, and consistently. If something needs sealing closed, is that intuitive, is there a finger-lift to the sealing tape backing? Can the test kit packaging’s print and artwork live up to a brands' wider portfolio of products?

HCP: As new regulations abound, and new sustainability concerns are raised, how does packaging address these areas?

Parker: First off, be aware of what regulations might relate to you now and in the medium- long term. We can look at addressing requirements from a number of different angles, but it ultimately comes back to expecting more from the packaging and working toward that.

Can the packaging help encourage correct use of the test, does it suitably protect the kit on its journey to the user, does it suitably protect the sample going to the lab? If it doesn’t do these things, then there’s an increased chance everything needs repeating – a new kit created, its journey to and from the user, retesting at the lab. There’s a lot of waste that could be reduced.

We could be looking at materials in more detail. For example, in case of paperboard already widely recyclable, we could also look at whether it comes from FSC certified forests. We could look at the sustainability credentials of the mill. We can look at reducing the total packaging volume. We can look at manufacturing efficiencies – for example, designing components for maximum sheet usage. We can take a step back and look at the supply chain. Can we manufacture closer to where the packaging is needed, and the distance things need to travel?