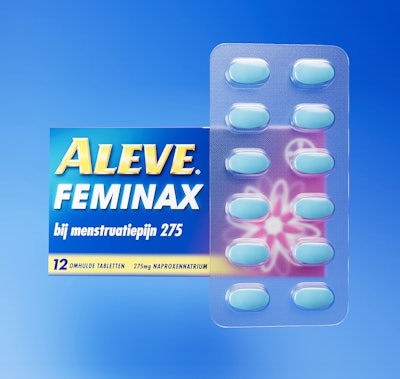

Bayer has launched a first-of-its-kind in the healthcare industry, polyethylene terephthalate (PET) blister packaging on its well-known brand, Aleve. Realized in partnership with pharmaceutical packaging specialist, Liveo Research, the new package has a significant reduction in emissions (38% CO2 by unit) and is 18% lighter compared with the current packaging, which is a blend of PVC and aluminum.

The updated pack is a mono-material PET that aligns with the company’s long-term goal of moving away from using PVC. Four years ago, before legislation surrounding sustainability intensified, Bayer defined its sustainability ambitions and in 2021, these goals were publicly released, focusing on removing PVC and moving toward recycle-ready packaging.

“In addition to our commitment to sustainable practices, we are facing significant pressures from consumers, customers, and legislative bodies,” says Chris Padain, VP, Global Head of Product Experience, Design & Packaging at Bayer Consumer Healthcare. “The most urgent of these pressures stem from initiatives such as the Packaging and Packaging Waste Regulation (PPWR) and the extension of California's Proposition 65. While Europe benefits from more cohesive legislation, various states in the U.S. are also advancing their own regulations. The challenges associated with blister packaging are particularly pertinent as we approach the next years, and addressing these issues remains a critical focus for us.”

Blister packaging, a key challenge, is a major focus area for the company as a substantial proportion of the company’s non-recycle-ready packaging consists of blister packs. By focusing on mono-material solutions, Bayer aims to implement solutions to enable recycling processes and contribute to packaging circularity.

“Our goal is to reduce PVC and make leading steps toward recyclable, or recycle-ready solutions,” says Padain.

Overcoming challenges

Blister packaging, widely used in over-the-counter products, has long posed a challenge for environmental sustainability due to its multilayer composition of plastic and aluminum, which makes it hard to sort and recycle. And since 30% of Bayer’s products are packaged in blister packs, this became a priority focus.

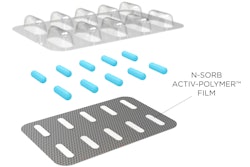

Bayer and Liveo Research were able to create a mono-material blister that offers the product protection and user friendliness the pack needed. Plus, the materials required minimal changes to existing infrastructure (packaging machinery). Since the processability of PET is similar to PVC, this allowed simple adaptations rather than replacement of equipment.

“From a manufacturing standpoint, no major adjustments were needed,” says Padain.

This doesn’t mean that the project did not have its trials. Padain says that the team had to overcome obstacles in managing actively regulatory approvals and even some hiccups in the printing, but the biggest one was the usability of the PET to deliver the expected consumer experience.

“The biggest challenge was achieving a consistent and user-friendly approach to pushing tablets through the plastic lidding, as plastic doesn't naturally wish to be perforated like aluminum does,” says Padain.

The team at Bayer had to be sure that the PET would allow the pills, whether gel caps or hard tablets, to puncture the material for access to the medication. So, the company focused on consumer research to ensure a positive user experience across different tablet forms and dimensions.

“Seventy percent of the R&D went to how to achieve a consistent and acceptable experience for the consumer,” says Padain.

Extensive testing and research helped the company understand user experiences and preferences, guiding adjustments to packaging design. And in the case of the Aleve blister packs, Padain says the performance is great, but this current specification may not be a solution for the company’s entire blister portfolio.

“It won't necessarily cascade everywhere,” says Padain. “We have soft chewable tablets, for instance, in our portfolio, that this PET solution will not necessarily solve.”

Bigger goals

While transitioning over-the-counter medicine packaging from PVC to PET is a step forward in sustainable packaging, change within the recycling industry is required to ensure innovations like this become part of the circular economy. Bayer is working across the industry in partnership with the Global Self-Care Federation and the Blister Pack Collective, and recently joined The Recycling Partnership, to accelerate progress and create systemic change.

“We're often asked why… ‘why do this if, if there's still work to be done?’ But our perspective is certainly this is the first step, and I think we've got to make that first step,” says Padain.

Launching first in the Netherlands, in the coming years, the company has the ambition to replace all its blister packaging with more sustainable alternatives. This initiative is a step forward and positions Bayer to meet future standards and legislative requirements, supporting the company’s broader goals of carbon reduction as it works toward larger Net Zero ambitions.